All components go through the strictest standards. Other than a devoted team to the quality of our products, we also have the equipment to assure that all critical measurements do not go unmeasured and all functions do not go untested.

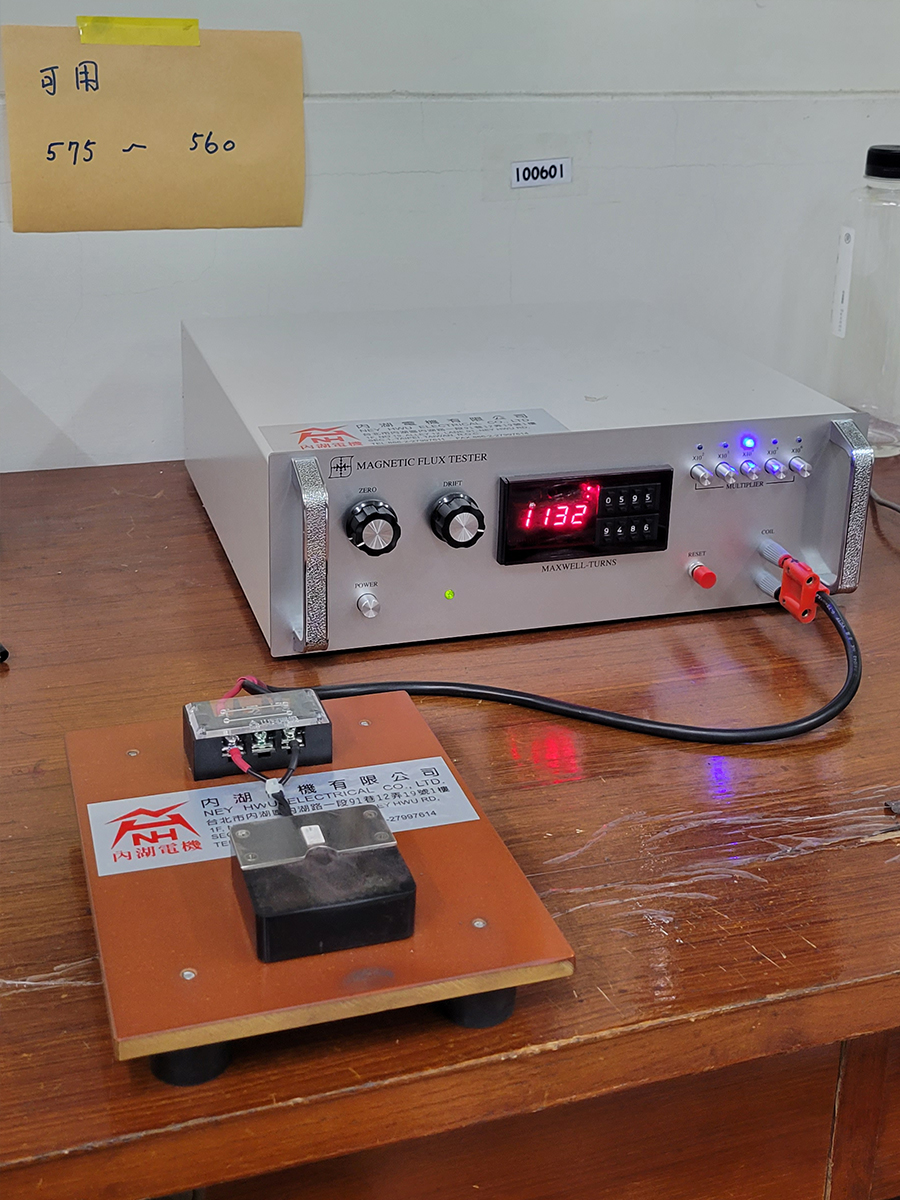

Gauss Meter

Used to evaluate the “strength” of a magnet. All magnets must be of equal and uniform strength to assure the functionality and longevity of our in-house solenoid valves.

Water Test Bench

Before any goods are delivered, we must test the functionality of our sensor faucets at various water pressures. Here we make sure the sensor faucet functions properly and doesn’t leak.

Solenoid Valve Test Bench

Solenoid valves go through 100% inspection. Solenoid valves are tested at 20, 60, and 150 psi.

Control Module Test Bench

After the control box of our sensor faucet is assembled, they go through 100% inspection on our custom-made test bench. All control boxes are tested for 30 minutes at 20 psi and another 30 minutes at 125 psi.

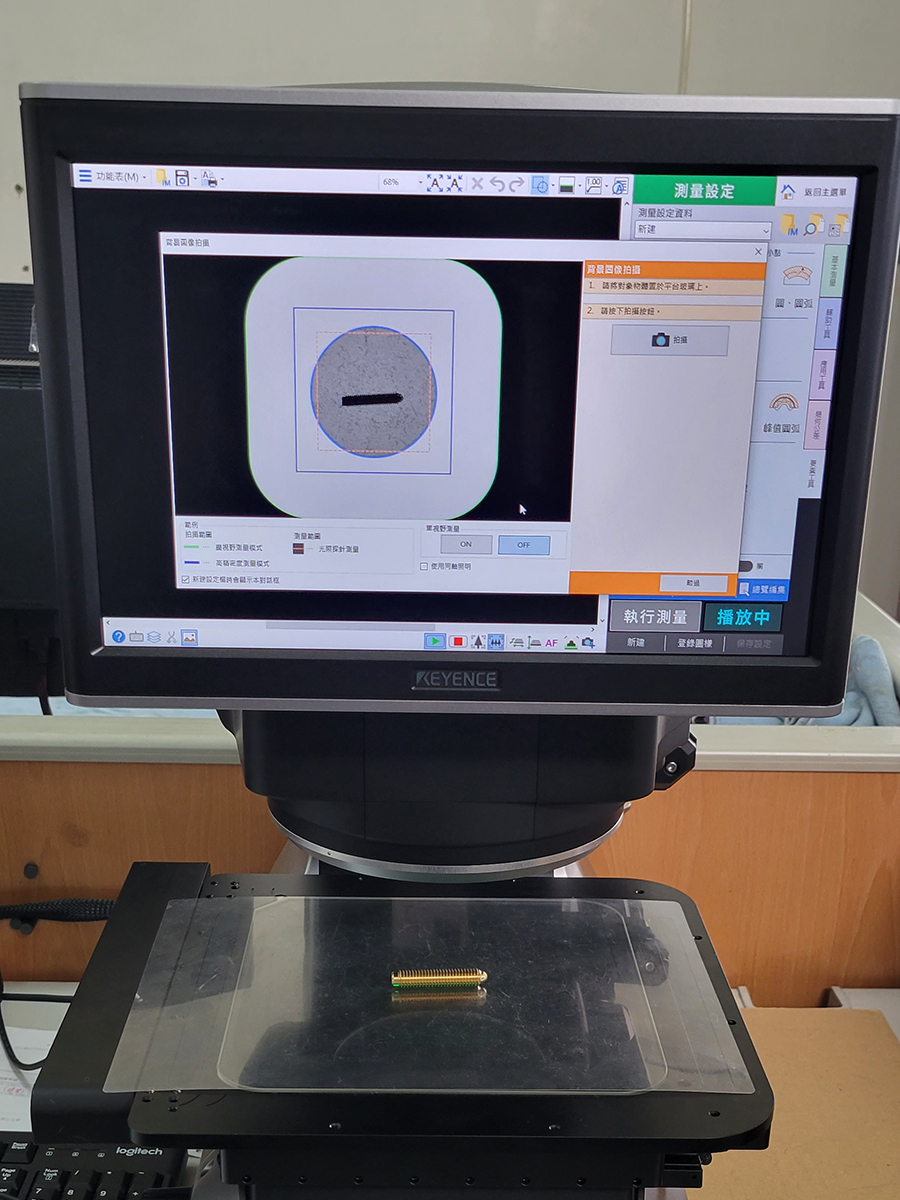

Image Dimension Measurement Machine

All critical components must be projected on this machine.